electrical discharge machining pdf

Wherein r is a radius of the thin wire electrode R is a radius of the coaxial cylinder external electrode and V corona ignition voltage. This rule is part of the.

Applied Sciences Free Full Text Principles And Characteristics Of Different Edm Processes In Machining Tool And Die Steels Html

The rule may be found at Title 40 Code of.

. Discharge to a safe place outside the workroom or if inside discharge at least above head height. The properties and effects of electric discharges are useful over a wide range of magnitudes. Tool High power sine wave generator This unit converts low frequency 60 Hz electrical power to high frequency 20kHz electrical power.

Advanced Manufacturing Processes PDF Full book by badebhau 1. A KSawhney-A course in Electrical and Electronic Measurements and Instrumentation. BS EN 144912006 specifies the basic design requirements for selecting a dust explosion venting system.

Prevent a discharge of oil into navigable waters or adjoining shorelines. Das Funkenerodieren kurz EDM von englelectrical discharge machining. Machining and machine-tools 2013.

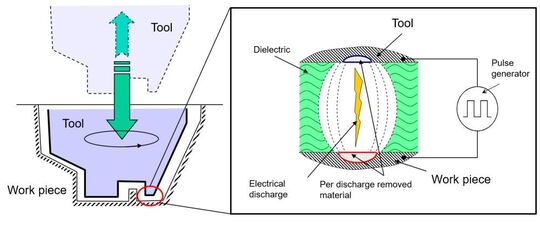

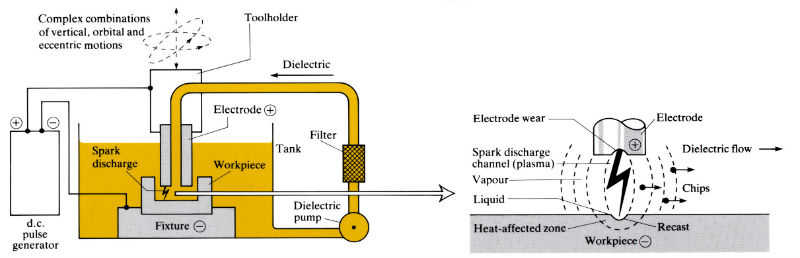

Corona discharges consist of relatively low-power electrical discharges at or near atmospheric pressure. Electrical Discharge Machining EDM The electrical discharge machining is also called as electro-discharge or spark erosion machining based on the erosion of metal by spark discharges. An electric arc or arc discharge is an electrical breakdown of a gas that produces a prolonged electrical dischargeThe current through a normally nonconductive medium such as air produces a plasma.

The materials are located between the top and bottom of the electrode after which the computer decides how much electrical discharge the electrodes produce. Metal Forming Roll forming High velocity hydro forming High velocity Mechanical Forming Electromagnetic forming High Energy Rate forming HERF Spinning Flow forming Shear Spinning Unit II. Enclosed sock or fabric filter collectors 25 m3s The enclosure should be strong with explosion vents that discharge to a safe place.

Working Advantages Disadvantages More with PDF In the previous article we had discussed Electron Beam Machining Ultrasonic Machining Electrical Discharge Machining and Electrochemical machining whereas in todays article we will learn various concepts of Water Jet Machining along with its Definition. Auch funkenerosives Bearbeiten funkenerosives Abtragen oder elektroerosives Bearbeiten ist ein thermisches abtragendes Fertigungsverfahren für leitfähige Materialien das auf elektrischen Entladevorgängen zwischen der Elektrode als Werkzeug und dem leitenden Werkstück beruht. Full PDF Package Download Full PDF Package.

Tiny pulses of current are used to detect ionizing radiation in a GeigerMüller tubeA low steady current can be used to illustrate the spectrum of gases in a gas-filled tubeA neon lamp is an example of a gas-discharge lamp useful both for illumination and as a voltage. Download Free PDF Download PDF Download Free PDF View PDF. Transducer The high frequency electrical signal is transmitted to traducer which converts.

Working Advantages Disadvantages More with PDF In the previous article we had discussed Electron Beam Machining Ultrasonic Machining Electrical Discharge Machining and Electrochemical machining whereas in todays article we will learn various concepts of Water Jet Machining along with its Definition. Ultrasonic Machining consists of. High Power sine wave generator 2.

The electric discharge CNC machines take advantage of this by designing controlled sparks to reshape materials. The plasma may produce visible lightAn arc discharge is characterized by a lower voltage than a glow discharge and relies on thermionic emission of electrons from the. Environmental Protection Agencys oil spill prevention program and was published under the authority of Section 311j1C of the Federal Water Pollution Control Act Clean Water Act in 1974.

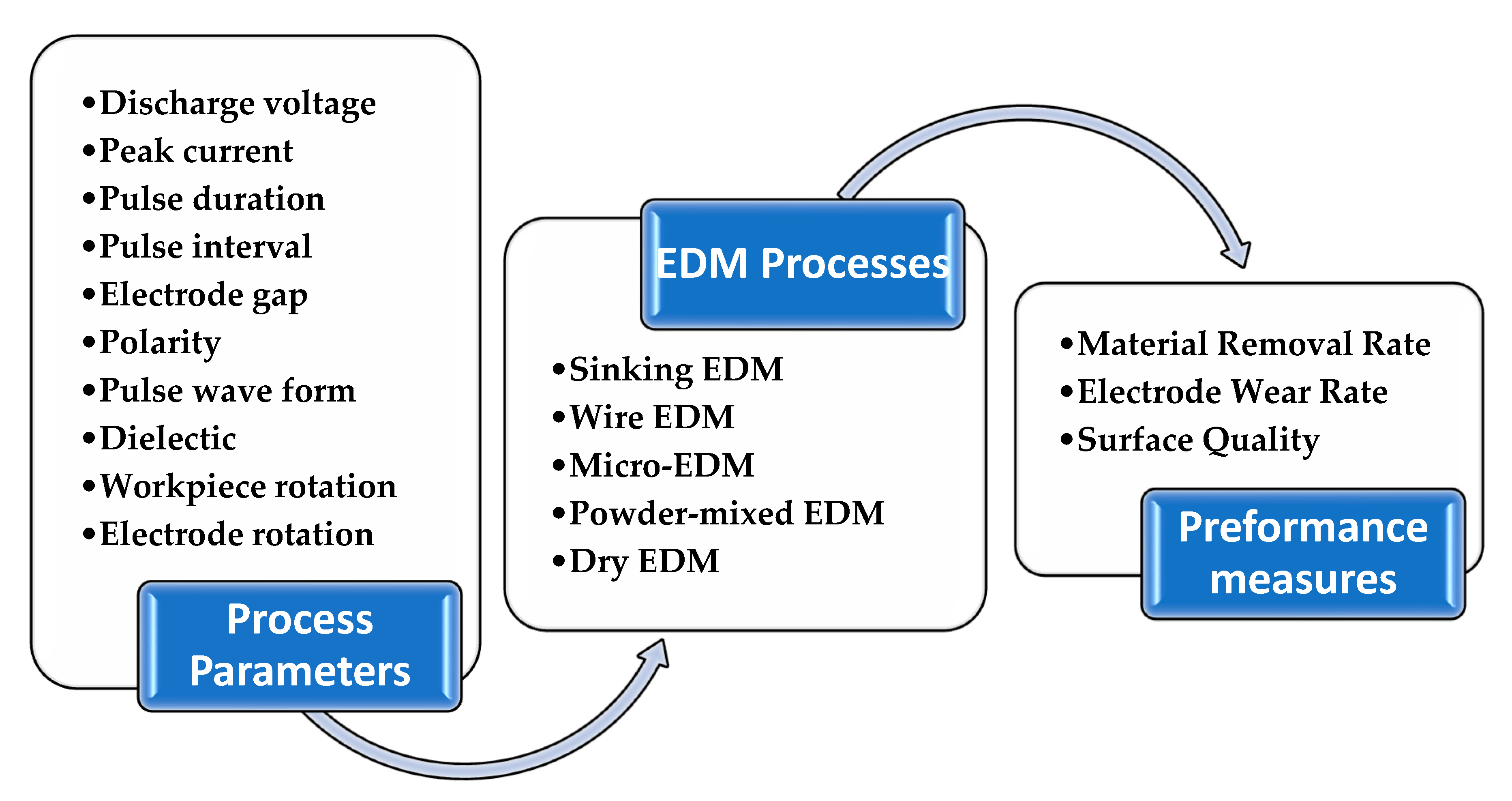

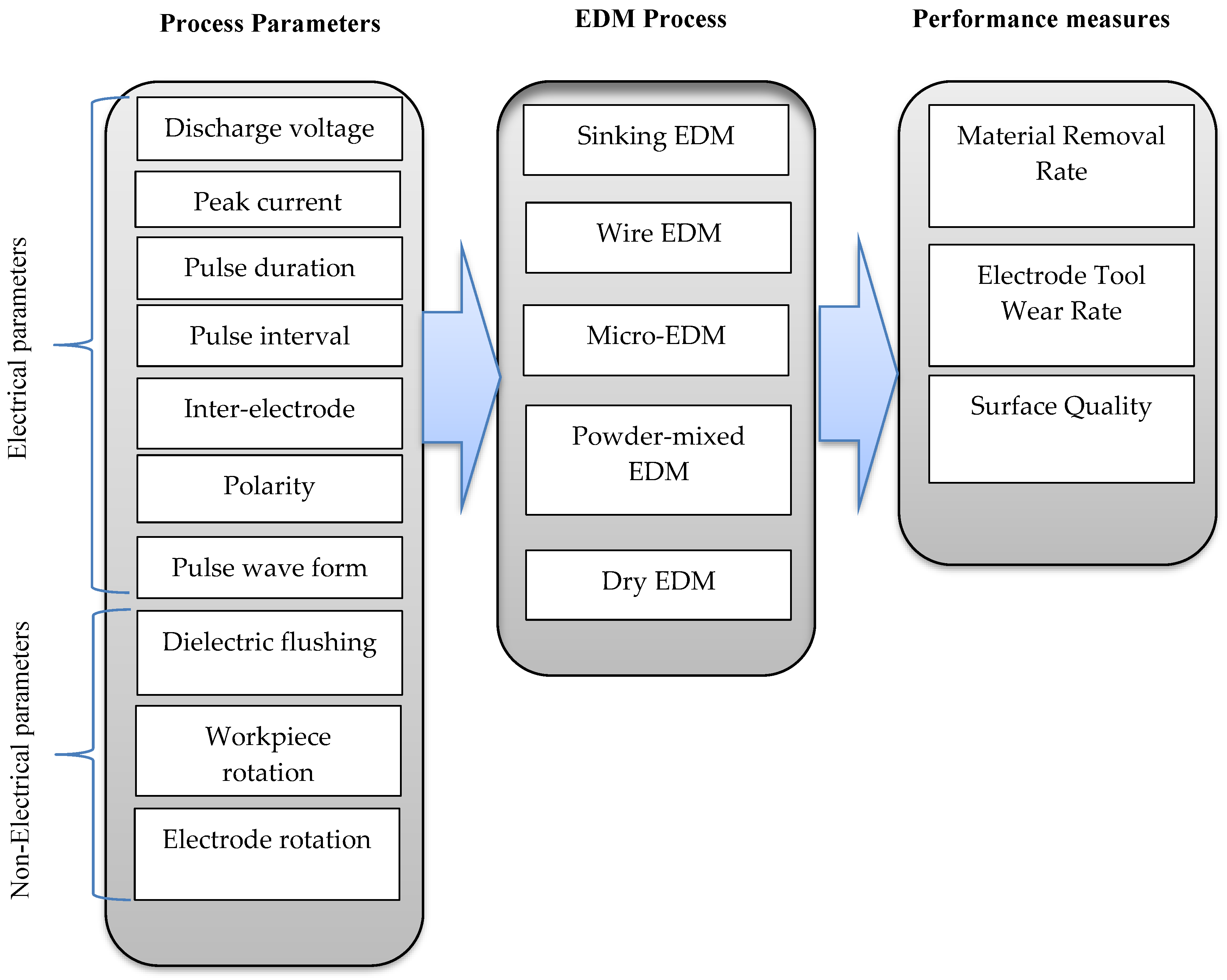

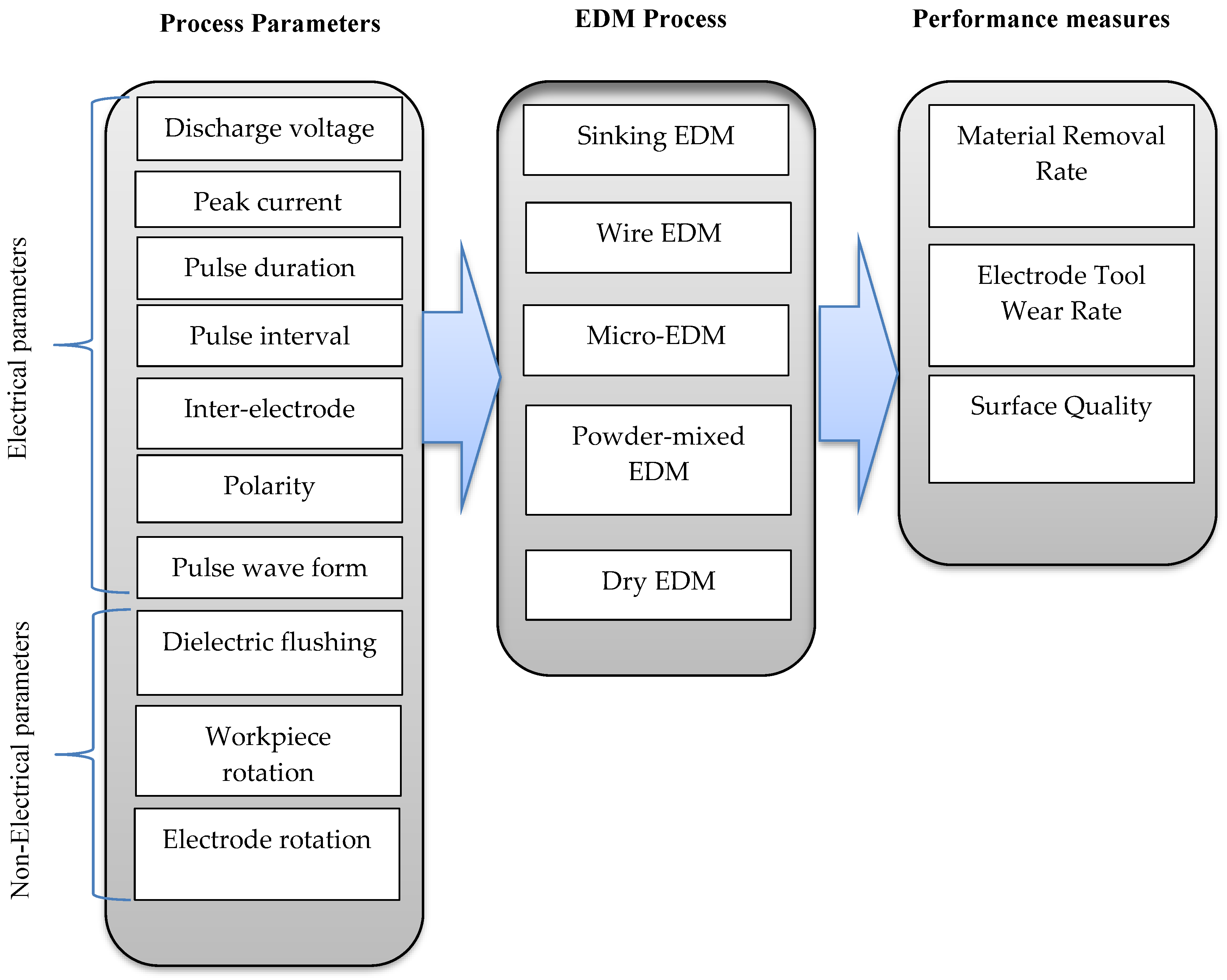

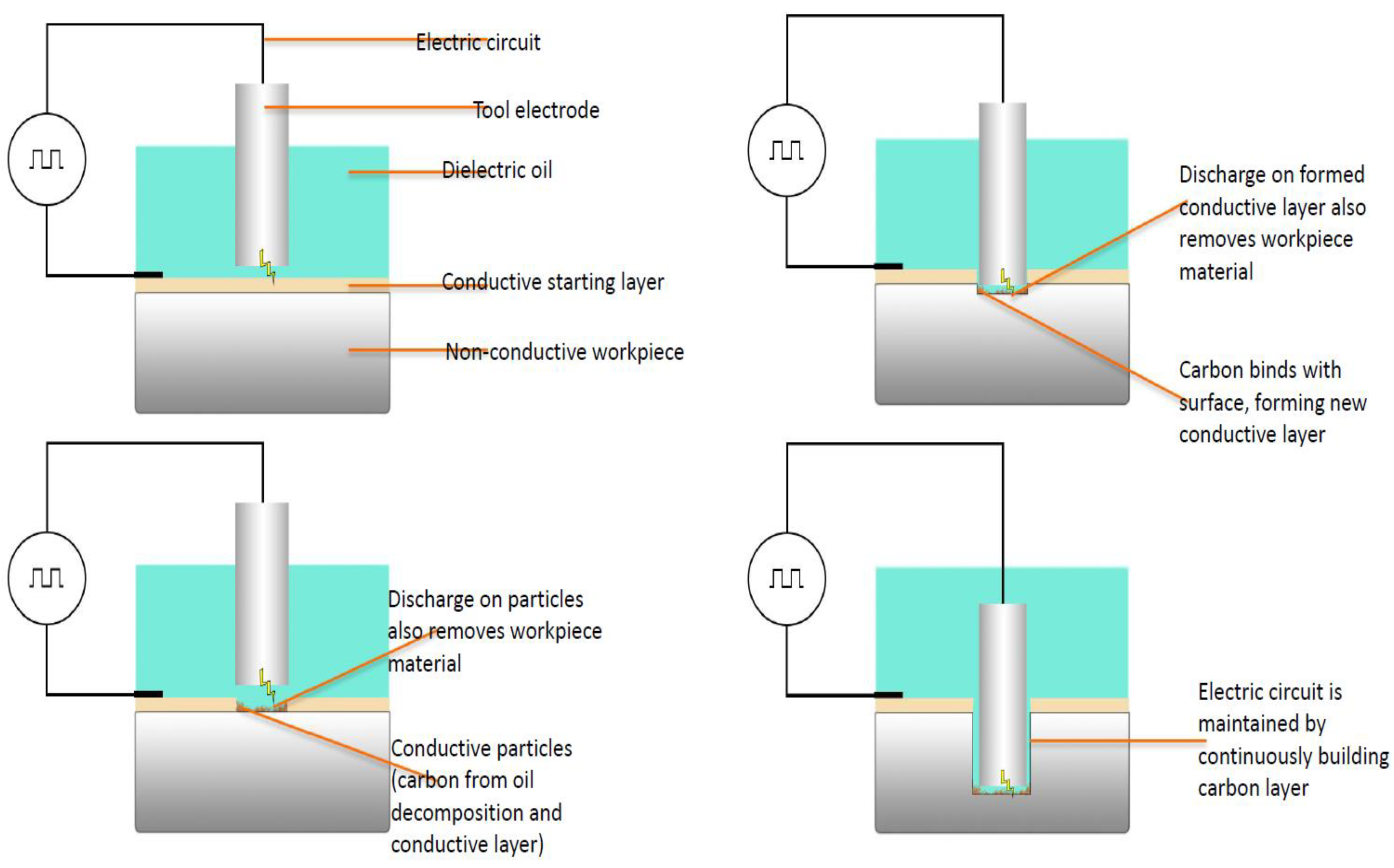

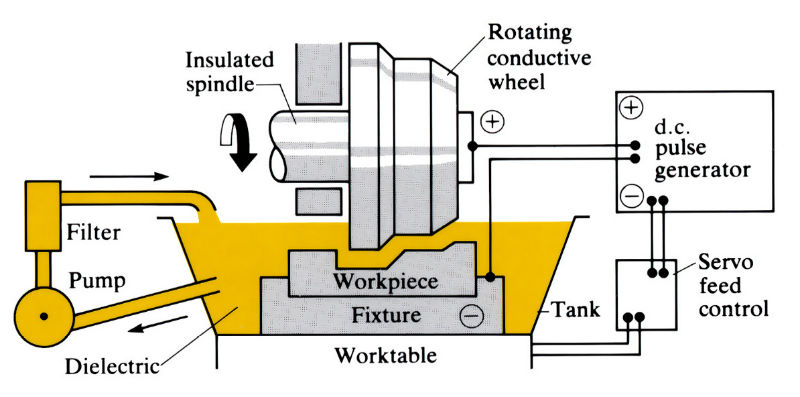

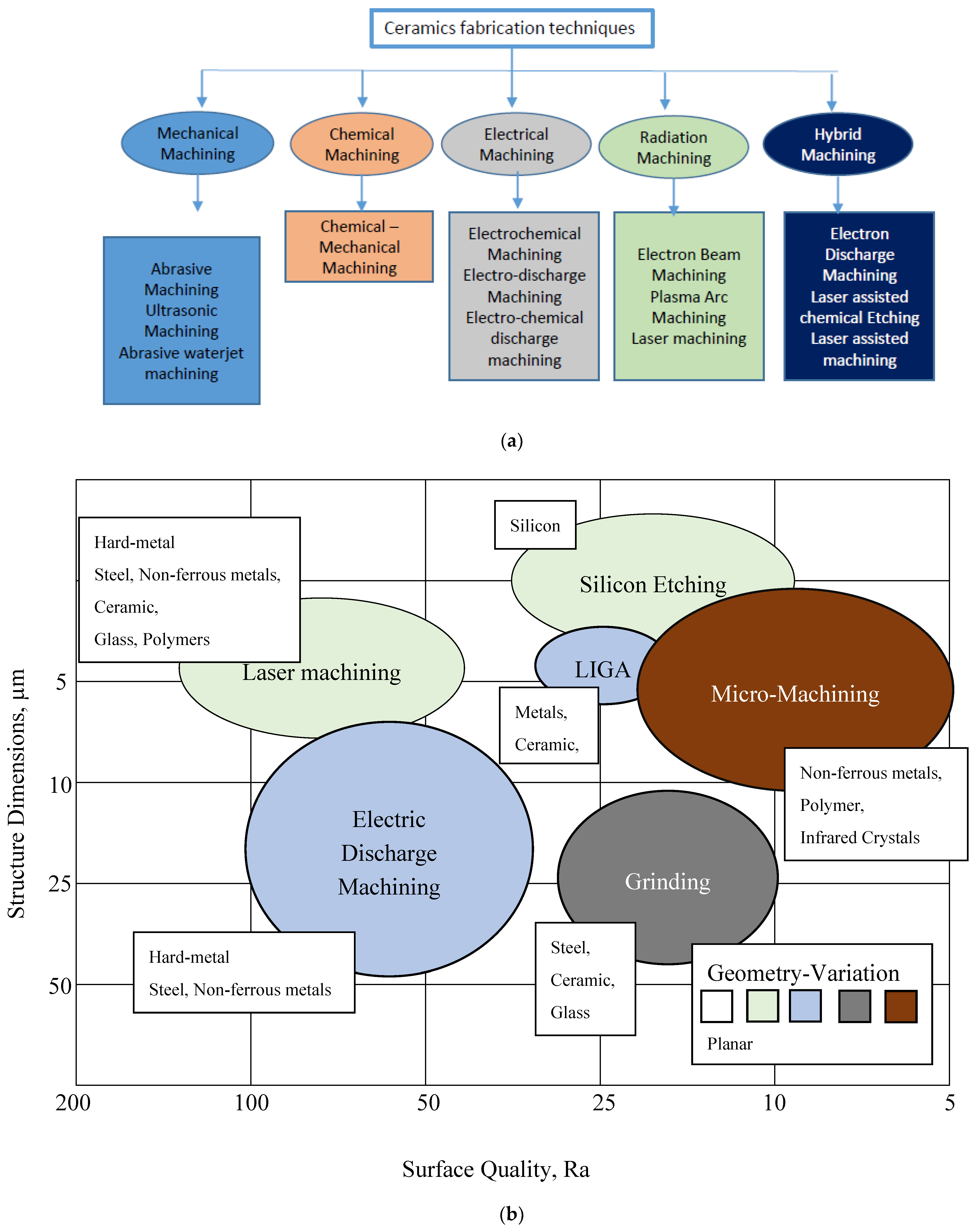

Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools called electrodes and the part being machined in the presence of a dielectric fluid. The basic EDM system consists of the shaped tool electrode and the workpiece connected to a DC supply and placed in a dielectric electrically non. CLASS NOTES ON ELECTRICAL MEASUREMENTS INSTRUMENTATION 2015 CLASS NOTES ON.

Question and answers Electrical Maintenance UnitQuestion and answers Electrical Maintenance UnitCT PT CC WATT METER PC Question and answers Electrical Maintenance UnitPresence oxidation. For example corona discharges generated in air at atmospheric pressure around a thin wire r 01 cm R 10 cm V corona ignition voltage 30 kV.

Materials Free Full Text Advanced Electric Discharge Machining Of Stainless Steels Assessment Of The State Of The Art Gaps And Future Prospect Html

Micromachines Free Full Text Electro Discharge Machining Of Ceramics A Review Html

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

What Is Electrical Discharge Machining And How Does It Work

Electric Discharge An Overview Sciencedirect Topics

Gate Ese Electrical Discharge Machining In Hindi Offered By Unacademy

Multi Wire Electrical Discharge Slicing Technology R D Highlights Research Mitsubishi Electric Global Website

Electrical Discharge Machining Principle Working Equipment S Advantages And Disadvantages With Diagram Mech4study

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Micromachines Free Full Text Electro Discharge Machining Of Ceramics A Review Html

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Electro Discharge Machining Working Parts Advantage Application Pdf

Electric Discharge Machining An Overview Sciencedirect Topics

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Electro Discharge Machining Working Parts Advantage Application Pdf

Electro Discharge Machining Working Parts Advantage Application Pdf